POTATO

With our roots in the potato processing sector, FPS has become the partner of choice for potato processors around the world. From our hygienic French Fry tunnels to our robust Fryer Systems, FPS is capable of offering full End-to-End potato processing solutions. We set the standard for hygiene, efficiency, and run times for high quality production of various potato products. Whether you're looking for a piece of equipment or a full line, look no further than FPS.

applications

-

battered

unbattered

wedges

all cuts

-

tater tots

hashbrowns

extruded products

OUR TECHNOLOGIES

End-to-end

From raw receiving to packaging, FPS can provide whole or partial line solutions large and small, from engineering to commissioning.

Freezer Tunnels

IQF airflow technology, Synchro SD™ Defrost, and Clean-in-Place solutions makes FPS the number one choice.

Spiral Freezers

Spiral freezers lead in hygienic construction and design to ensure smooth, food safe surfaces. As the only OEM to offer 72” (1.8m) DirectDrive belting option, our custom solution provides greater production and capacity.

fryer systems

More than 50 years of building, servicing, and retrofitting fryers has led to the most robust, custom built French Fry fryers and Specialty fryers with the best oil flow in the industry.

Blanchers

GEM's custom designed hump belt blanchers and rotary blanchers are the most consistent in the industry. 2-Zone and Multi-Zone belt blanchers are offered for any capacity required.

Dryers / Retrograders

Product that has been blanched or washed is dewatered and evenly distributed on the dryer belt for even bed depth across belt width for optimal drying.

PEF Dual Conveyor Chamber Treatment

It is specifically designed for the solid food processing industry and brings distinct advantages to the potato sector by softening the potato tissue, minimizing breakage and feathering during cutting.

Conveyance / Product Handling Systems

We custom engineer conveyance and product handling systems for various industry types and food factory settings.

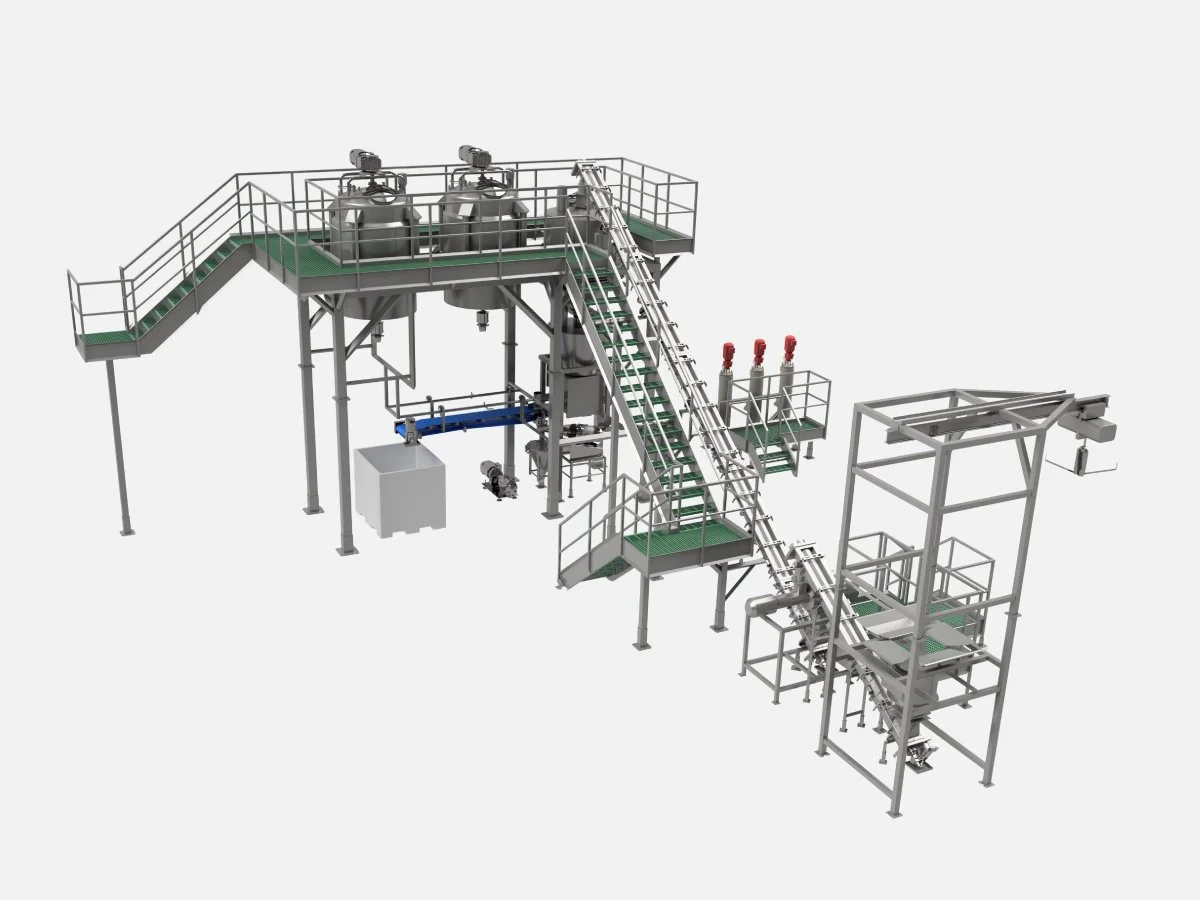

Batter Mixers

Complete batter mix system and applicator conveyor for today’s modern French Fry plant.

Batter Applicator

Potato strips are immersed in a prepared batter mixture run through conveyors or dipping system to ensure even coating and complete coverage before frying.

SAPP

Sodium acid pyrophosphate (SAPP) and dextrose are typically applied to French Fries or diced potato in a specialty line to help control color and other quality aspects of the finished product.